Language :

Language :

![]()

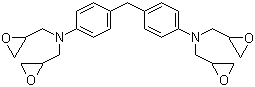

YLSE-721 is a tetrafunctional epoxy resin. It is designed for fabricating high-temperature performance composites by the filament winding process. This system exhibits long pot life at process temperatures, yielding systems with high glass transition temperatures and excellent retention of mechanical performance, even at elevated temperatures.

![]()

YLSE-721 is a high-temperature resistant epoxy resin of tetrafunctional glycidylamine type. The molecular structure of this epoxy resin contains multiple epoxy groups and aromatic rings. During the curing process, it can form a high crosslinking density and aromatic density, making the cured product exhibit excellent heat resistance, high mechanical strength, low curing shrinkage rate, good radiation resistance, water resistance and chemical resistance. In addition, due to its low viscosity, it is easy to operate and can be used for solvent-free operation. It is suitable for electrical casting insulation products with high heat resistance requirements, as well as for the production of composite materials through carbon fiber and glass fiber winding, pultrusion, lamination and prepreg processes.

![]()

CAS No.:28768-32-3

![]()

| YLSE-721L | YLSE-721C | YLSE-721 | |

| Appearance | Light yellow liquid | Light yellow liquid | Light yellow liquid |

| Color, Gardner | ≤10 | ≤10 | ≤10 |

| Viscosity, cps@50°C | 6000~11000 (25°C) | 3000~7000 | 3000~7000 |

| EEW, g/eq | 110-125 | 110-125 | 105-120 |

| Volatiles, % | ≤0.6 | ≤0.6 | ≤0.6 |

| Differences | Lower Viscosity | Lower Price | High Purity |

![]()

Fast curing speed at room temperature, excellent long-term high-temperature resistance

Good mechanical strength and durability

Low curing shrinkage rate

Low viscosity, good processability

Good chemical corrosion resistance and radiation resistance

![]()

Carbon fiber and glass fiber composite materials

200 - 260℃ temperature-resistant structural adhesive

Laminated board

Electrical insulating material

![]()

Store in well-ventilated area. Keep away from flames and direct sunlight. Close the cap tightly immediately after use.

All safety information is provided in the Material Safety Data Sheet.

![]()

At least 12 months from the date of manufacture in the original packing in ambient temperatures.

![]()

Drum package.