Language :

Language :

Product Description

YLSE-0500 / YLSE-0510 is a high-temperature-resistant trifunctional epoxy resin based on p-aminophenol. The molecular structure contains multiple epoxy groups and aromatic rings, enabling the cured system to form a high crosslink density and aromatic density during curing. As a result, the cured material exhibits excellent heat resistance, high mechanical strength, low curing shrinkage, and good resistance to radiation, water, and chemicals.

In addition, its low viscosity makes it easy to process and suitable for solvent-free operations. It is used in electrical insulation castings requiring high thermal resistance, as well as composite manufacturing processes such as carbon fiber and glass fiber filament winding, pultrusion, lamination, and prepreg production. The glass transition temperature (Tg) can exceed 200 °C.

Product Name

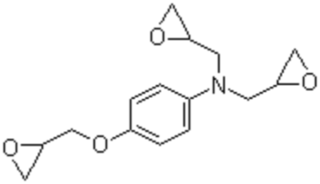

4-(2,3-Epoxypropoxy)-N,N-di(2,3-epoxypropyl)aniline

CAS No.: 5026-74-4

Structural Formula

|

|

YLSE-0500 |

YLSE-0510 |

|

Appearance |

Brown liquid |

Yellow liquid |

|

EEW, g/eq |

100-115 |

93-106 |

|

Viscosity, cps@25°C |

1500-6000 |

500-1000 |

|

Volatiles, % |

Max. 1.5 |

Max.1.0 |

Main Applications

High-temperature structural adhesives

Carbon fiber and glass fiber composites for pultrusion and filament winding

Electrical insulation materials

High-temperature epoxy casting systems used in vacuum casting (RTM, VARTM) and Automatic Pressure Gelation (APG)

Potting and sealing of miniature motor components

High-temperature epoxy diluent

Comparison of Casting Performance between YLSE-0500 and YLSE-0510

Using DDS (4,4'-diaminodiphenyl sulfone) as the curing agent, selected performance properties of castings made from YLSE-0500 and YLSE-0510 epoxy resins were tested.

Casting preparation procedure:

• Heat DDS to 200 °C (melting point 176 °C) until melted.

• Preheat the epoxy resin to 100 °C.

• Slowly add DDS into the epoxy resin while stirring until uniform.

• Defoam under vacuum for 15 minutes.

• Pour into molds and heat-cure.

The performance indicators of the resulting castings are shown in the table below:

|

Brand type |

YLSE-0500 |

YLSE-0510 |

|

Curing agent name |

DDS |

|

|

Curing agent addition amount phr |

49 |

|

|

Curing condition |

0.5h/80°C+1h/100°C+1.5h/120°C+2h/180°C |

|

|

Tg(DMA method) °C |

245-250 |

260-270 |

|

Bending performance at 25°C |

||

|

Strength Mpa |

132 |

136 |

|

Modulus Gpa |

3.5 |

3.4 |

|

Tensile properties at 25°C |

||

|

Strength Mpa |

64 |

70 |

|

Modulus Gpa |

3.8 |

3.6 |

|

Elongation at break % |

2.3 |

2.8 |

Casting Properties of YLSE-0500 with Methyl Tetrahydrophthalic Anhydride (MTHPA)

YLSE-0500 epoxy resin is commonly used together with aromatic amine curing agents (such as diaminodiphenyl sulfone and diaminodiphenylmethane) and anhydride curing agents (such as methyl nadic anhydride, methyl tetrahydrophthalic anhydride, and methyl hexahydrophthalic anhydride).

The casting properties of YLSE-0500 cured with methyl tetrahydrophthalic anhydride (MTHPA) at 25 °C are shown in the table below:

|

Tensile strength Mpa |

Bending strength Mpa |

Impact strength Kj/m2 |

Elongation at break % |

Tg(DSC) % |

|

20-30 |

90-100 |

8-10 |

1.5-2.5 |

190-200 |

|

Mixing ratio(Phr): YLSE-0500/MTHPA=100/150 Curing conditions: 80℃/2h+100℃/2h+130℃/2h+180℃/3h |

||||

Precautions

Due to its high functionality and high epoxy value, the curing process generates a large amount of heat, so attention must be paid to preventing runaway polymerization. If the viscosity becomes too high and causes difficulty in use, the resin may be heated to 100–120 °C for 1 hour to reduce the viscosity. During heating, please open the container lid to prevent any risk of runaway polymerization.

Equivalent Grades

Similar domestic and international product grades include MY-0500, MY-0510, AFG-90, AFG-90H, etc.