Language :

Language :

Why is YLSE-721 our star product? What makes it so “hardcore”?

YLSE-721 is a high-performance, amino-based tetrafunctional liquid epoxy resin — an “industrial-grade bonding master” designed specifically for high-strength and high heat-resistant applications.

Its name reveals the secret: “tetrafunctional” means each molecule contains four reactive sites, like a “multi-armed warrior” that can form a denser and stronger cross-linked network with curing agents. This is the key reason why its strength far exceeds that of ordinary difunctional epoxy resins. Meanwhile, its liquid form provides excellent flowability, making it ideal for potting, coating, or filling complex structures, ensuring easy and efficient application.

What truly impresses users are its “three highs”: high temperature resistance, fast curing, and superior mechanical strength.

Heat resistance: Continuous service temperature up to 150°C, and short-term endurance above 180°C, far outperforming standard epoxies (typically ≤120°C). Perfect for engine surroundings, motor coils, and PCB protection under high-temperature conditions. 🔧

Curing speed: Fully cures within 30–60 minutes at 60–80°C, which is 2–3 times faster than conventional epoxy systems — a real time-saver for urgent projects.

Mechanical properties: Tensile strength exceeds 50 MPa, flexural strength surpasses 80 MPa, with excellent impact resistance and dimensional stability. It resists cracking even under severe vibration or thermal cycling.

In addition, YLSE-721 offers outstanding electrical insulation, oil resistance, water resistance, and chemical durability — truly earning its reputation as the “Iron Man of the industrial world.”

Product Information

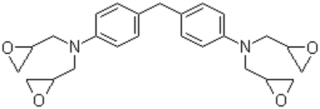

Chemical Name: N,N,N',N'-Tetraglycidyl-4,4'-diaminodiphenylmethane

CAS No.: 28768-32-3

Structural Formula

Main Applications

High-temperature resistant composites such as carbon fiber and glass fiber;

Potting of electronic components (e.g. power modules, LED drivers);

Impregnation and insulation protection for motors and transformer coils;

Precision mold manufacturing, including bonding of metals, ceramics, and composites;

Bonding and sealing of aerospace structural components;

Wear-resistant repair and anti-corrosion coatings for heavy-duty mechanical parts.

Usage Instructions

YLSE-721 can be formulated with amine-type, anhydride-type, or imidazole-type curing agents and coupling agents to prepare adhesives, casting compounds, or composite systems for applications requiring excellent heat resistance.

Common curing agents include 4,4'-diaminodiphenyl sulfone (4,4'-DDS), 4,4'-diaminodiphenylmethane (DDM), methyl tetrahydrophthalic anhydride (METHPA), methyl nadic anhydride (MNA), and 2-ethyl-4-methylimidazole (2,4EMI).

If the resin appears too viscous during use, it can be heated to an appropriate temperature to reduce viscosity before mixing.

To improve toughness, additives such as liquid polysulfide rubber or liquid nitrile rubber can be incorporated.

Typical Cured Properties

| DDS | DDM | METHPA | MNA | Test Method |

| Glass Transition Temperature (°C) | 250-260 | 220-230 | 200-210 | 235-240 |

| Tensile Strength (MPa) | 75 | 50 | 50 | 45 |

| Tensile Modulus (GPa) | 3.5 | 3.3 | 3.2 | 3.6 |

| Flexural Strength (MPa) | 130 | 120 | 100 | 97 |

| Flexural Modulus (GPa) | 3.3 | 3.4 | 4.0 | 3.8 |

| Elongation at Break (%) | 2.8 | 1.6 | 1.9 | 1.1 |

| Impact Strength (kJ/m²) | 15 | 10 | 9 | 8 |

| Resin-to-Hardener Ratio (by weight) | 100:52 | 100:42 | 100:42 | 100:150 |

| Curing Schedule | 100℃*2h+130℃*2h+160℃*2h+180℃*2h+200℃*2h | |||

Common Mistakes to Avoid

❌ Incorrect curing agent combination: YLSE-721 must be used with specific anhydride or aromatic amine curing agents. Using general-purpose epoxy hardeners may result in incomplete curing, soft texture, or drastically reduced heat resistance ⚠️.

❌ Neglecting surface preparation: The substrate must be thoroughly cleaned, dried, and sanded; otherwise, adhesion failure or “false bonding” may occur.

❌ Overheating during curing: Although the resin has high thermal resistance, curing should be kept within the recommended temperature range (usually 60–120°C). Excessive temperature may cause bubbling or discoloration.

Precautions

Due to its high functionality and epoxy value, YLSE-721 releases a large amount of heat during curing, so precautions should be taken to prevent runaway polymerization.

If the viscosity is too high for convenient use, preheat the resin to 100–120°C for about one hour to lower viscosity.

⚠️ When heating, keep the container lid open to prevent polymerization explosion.

This epoxy resin is alkali-resistant but not resistant to strong acids.